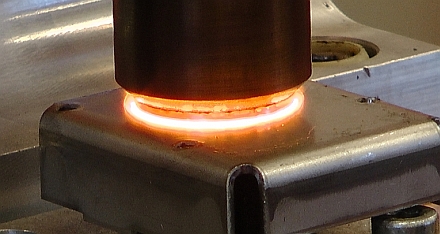

Resistance welding is a welding process for electrically conductive materials based on the Joule heating of an electrical current flowing through the connection point. This heats up the connecting parts until they fuse. A welded joint results after the current flow and the re-solidification of the melt. By pressing the parts together during and after the current flow, resistance pressure welding supports the formation of a deep connection.

[Source: http://de.wikipedia.org/wiki/Widerstandsschweissen]

ATEC products in resistance welding

Tubular radiator elements: Fully automatic medium-frequency annular projection welding system for welding head ends with tubes to produce radiator elements of varying dimensions (400mm to 3000mm).

Dimensions of < 400mm also optionally possible.

Bathroom radiators: Complete production line for the production of bathroom radiators. Punching, topping, cover welding, de-burring, welding vertical and horizontal tubes at various distances.

Cover welding machine: Medium-frequency welding system for gap-free welding of stainless steel covers on door handles.

Hub tap welding machine: The individual radiator elements are welded together at the two hubs through resistance pressure welding with up to 40 welding points.