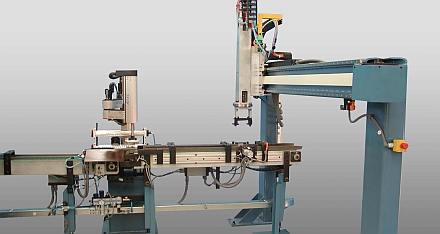

Head ends ground by a grinding machine are checked with image processing for defects such as "scratches", "dents", "rough grinding pattens" and "dashes". For this purpose a robot picks up the part and carries this past the camera, so that the inspection can take place on three sides. The parts are subsequently sorted automatically by an NC handling system into the respective categories "good", "rework" and "scrap".

Good parts: Are fed on for further processing

Rework parts: Are fed back to the personnel

Scrap parts: Are directly ejected

Key data:

Cycle time: 3sec/head end (incl. handling)

Capacity: 6 million parts in 3-shift operation

Efficiency: 95%